Revision 1.1

18 Mar 2015

Description:

This CFP Multi-Source Agreement (MSA) defines the CFP4 form factor of an optical transceiver to support 40Gbit/s and 100Gbit/s interfaces for Ethernet, Telecommunication and other applications. The members of the CFP MSA have authored this document to provide an industry standard form factor for new and emerging high speed communications interfaces. Specifications provided in this document are given as a “delta” to the CFP MSA Hardware Specification Rev.1.4, June 7, 2010 or the CFP MSA CFP2 Hardware Specification Rev. 1.0, July 31, 2013.

CONTENTS

Draft | Date | Revised Items |

0.1 | 3/2/2014 | Initial draft, based on CFP4 Baseline Design, Revision P |

0.2 | 6/28/2014 | 2nd draft, based on revised CFP4 Baseline Design, Revision R. Some editorial errors were corrected in Rev.R Added description on Pin-out definition. |

1.0 | 8/28/2014 | First Official Release, based on CFP4 Baseline Design, Revision R |

1.1 | 3/18/2015 | Reference Document, reflecting MIS latest version Table.1-1, corrected note.1 as per MIS definition on Programmable Control 1 |

Table 1-2: Hardware Alarm Pins 10

Table 1-3: Management Interface Pins (MDIO) 11

Table 4-1: Voltage Power Supply 16

Table 4-2: Optional Reference Clock Characteristics 19

Table 4-3: Optional Monitor Clock Characteristics 20

Table 4-4: CFP4 Module Clocking Signals 20

Table 5-1: CFP4 Mechanical Characteristics 26

Table 5-2: CFP4 Module Insertion, Extraction Forces 26

Table 5-3: Optical Connectors 28

Table 5-4: CFP4 Host Connector Assembly 29

Table 5-5: CFP4 4x25Gbpt/s Pin Map 31

Table 5-6: CFP4 Bottom Row Piin Description for 4x25 Gbit/s Applications 32

Table 5-7: CFP4 Bail Latch Color Coding 33

Figure 1-1: CFP4 Functional Block Diagram 8

Figure 2-1: Reference +3.3V LVCMOS Output Termination 12

Figure 2-2: Reference 3.3V LVCMOS Input Termination 13

Figure 2-3: Reference MDIO Interface Termination 14

Figure 4-1: High Speed I/O for Data and Clocks 16

Figure 4-2: CFP4 Module Optional Loopback Orientation 17

Figure 4-3: Example of Clocking for 4 x 25 Gbit/s CFP4 Applications 21

Figure 4-4: Example of Clocking for 4 x 10 Gbit/s CFP4 Applications 21

Figure 5-1: CFP4 Module & CFP4 Module Mated in Host Quad Port System 22

Figure 5-2: Host Cage System and Mounting Method Overview 22

Figure 5-3: CFP4 Module Plug Connector Assembly 23

Figure 5-4: CFP4 Quad Port Host Connector Cover Assembly 23

Figure 5-5: CFP4 Host Connector Assembly 24

Figure 5-6: CFP4 Pin Map Connector Engagement 24

Figure 5-7: CFP4 Module Dimension Overview 25

Figure 5-8: Riding Heat Sink 27

Figure 5-9: Host Cage Top Surface Opening 27

Figure 5-10: CFP4 Connector Pin Map Orientation 30

Figure 5-11: CFP4 Module Label Recess 33

CFP MSA Hardware Specification, Revision 1.4, June 7, 2010.

CFP MSA CFP2 Hardware Specification, Revision 1.0, July 31, 2013.

CFP MSA Management Interface Specification, Version 2.4, March, 2015.

IEEE P802.3bm, 40Gbit/s and 100Gbit/s Operation Over Fiber Optic Cables Task Force,

http://www.ieee802.org/3/bm/index.html

IEEE Std 802.3TM-2012, Annexes 83A, 83B, and 86A.

IEEE Std 802.3TM-2012, Cl. 45, Management Data Input/Output (MDIO) Interface.

ITU-T Recommendation G.709 (2012) Interfaces for the Optical Transport Network (OTN).

ITU-T Recommendation G.707 (2007) Network node interface for the synchronous digital hierarchy (SDH).

OIF-CEI-3.0, http://www.oiforum.com/public/documents/OIF_CEI_03.0.pdf

SFF Committee INF-8077i 10 Gigabit Small Form Factor Pluggable Module

SFF Committee SFF-8431 Specifications for Enhanced Small Form Factor Pluggable Module SFP+

![]()

![]()

This CFP Multi-Source Agreement (MSA) defines the CFP4 form factor of an optical transceiver which can support 40Gbit/s and 100Gbit/s interfaces for Ethernet, ITU-T OTN and other applications. Specifications provided in this document are given as a “delta” to the CFP MSA Hardware Specification Rev.1.4 or the CFP2 Hardware Specification Rev. 1.0.

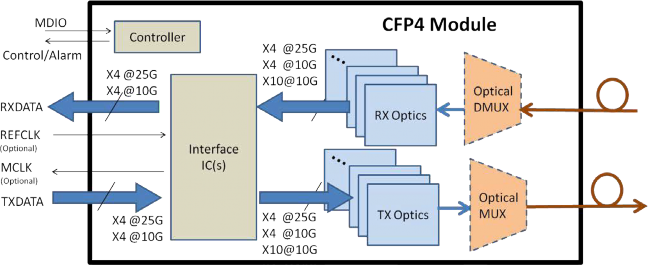

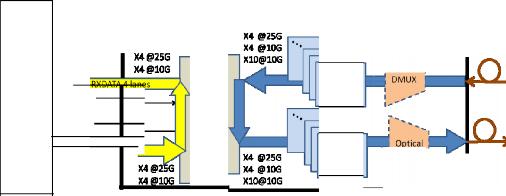

The CFP4 electrical interface will vary by application, but the nominal signaling lane rate is 25Gbit/s per lane and documentation is provided in OIF CEI-28G-VSR, CAUI-4, and OTL4.4 electrical interface specifications. The CFP4 electrical interface can also optionally support a nominal signaling lane rate of 10Gbit/s and documentation is provided in XLAUI, XLPPI, OTL3.4 and STL256.4. The CFP4 module may be used to support single mode and multimode fiber optics.

The CFP4 modules and the host system are hot-pluggable. The module or the host system shall not be damaged by insertion or removal of the module.

CFP MSA is an acronym for 100G1 Form factor Pluggable Multi-Source Agreement.

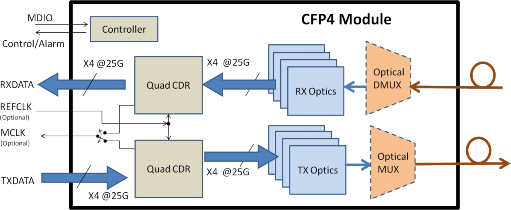

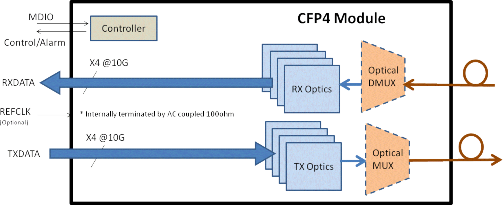

CFP4 FUNCTIONAL BLOCK DIAGRAM

Figure 1-1: CFP4 Functional Block Diagram

![]()

1 C = 100 in Roman numerals; Centum

The CFP4 module is a hot pluggable form factor designed for optical networking applications. The module size has been chosen to accommodate a wide range of power dissipations and applications. The module electrical interface has been generically specified to allow for supplier-specific customization around various “4 x 25Gbit/s” and 4 x 10Gbit/s interfaces.

A CFP4 module is defined to be hot pluggable. Hot Pluggable is defined as permitting module plugging and unplugging with Vcc applied, with no module damage and predictable module behavior as per the State Transition Diagram. As shown in Figure 5-6: Pin Map Connector Engagement, the Module Absent (MOD_ABS) pin and Module Low Power (MOD_LOPWR) pin are physically guaranteed to be one of the last pins tomate.

![]()

![]()

The control and status reporting functions between a host and a CFP4 module use non-data control and status reporting pins on the 56-pin connector. The control and status reporting pins work together with the MDIO interface to form a complete HOST-CFP4 management interface. The status reporting pins provide status reporting. There are three (3) Hardware Control pins, two (2) Hardware Alarm pins, and six (6) pins dedicated to the MDIO interface. Specification of the CFP4 hardware signaling pins are given in Ref.[1] with the following changes listed in this document.

Hardware Control Pins

The CFP4 Module supports real-time control functions via hardware pins, listed in

Table 1-1. Specifications of the CFP4 hardware control pins are given in Ref.[1], with the following changes listed below.

Pin # | Symbol | Description | I/O | Logic | “H” | “L” | Pull-up /down |

11 | TX_DIS (PRG_CNTL) | Transmitter Disable (Optionally configurable as Programmable Control after Reset1) | I | 3.3V LVCMOS | Disable2 | Enable2 | Pull – Up3 |

14 | MOD_LOPWR | Module Low Power Mode | I | 3.3V LVCMOS | Low Power | Enable | Pull – Up3 |

16 | MOD_RSTn | Module Reset, Active Low (invert) | I | 3.3V LVCMOS | Enable | Reset | Pull – Down4 |

1 When Programmable Control is configured, MSA Default is TXDIS.

2 Per CFP MSA Management Interface Specification [3] when PRG_CNTL is configured for this pin.

3 Pull-Up resistor (4.7 kOhm to 10 kOhm) is located within the CFP4 module

4 Pull-Down resistor (4.7 kOhm to 10 kOhm) is located within the CFP4 module

Hardware Control Pins: Functional Description

This control pin allows for the system to program certain controls via a Hardware pin. TX Disable Pin (TX_DIS) is optionally configurable as Programmable Control 1 Pin after Reset. When Programmable Control 1 is configured,

the default setting for Control 1 is control of the TX_DIS.

Programmable Control 1 Pin is an input pin from the Host, operating with programmable logic. This pin is pulled up in the CFP4 module. It can be re-programmed over MDIO registers to another MDIO control register while the module is in any steady state except Reset. The CFP MSA specifies that the default function be TX Disable (TX_DIS) with active-high logic. If the other function besides TX_DIS is configured for this pin, there is no way to assert TX disable via a hardware pin.

Not supported in CFP4 module

Not supported in CFP4 module

Not supported in CFP4 module

TX Disable Pin (TX_DIS) is an input pin from the Host, operating with active-high logic. This pin is pulled up in the CFP4. When TX_DIS is asserted, all of the optical outputs inside a CFP4 module shall be turned off. When this pin is de-asserted, transmitters in a CFP4 module shall be turned on according to a predefined TX turned-on process which is defined by the state diagram shown in the “CFP MSA Management Interface Specification”. A maximum time is defined for the transmitter turn-on process. This time is vendor and/or technology specific and the value is stored in a MDIO register.

This pin can be optionally configured as Programmable Control 1 Pin after Reset. One MDIO register which defines if the module supports this optional configuration or not is prepared in NVR region.

Please refer to Ref.[3] for more details.

The CFP4 Module supports alarm hardware pins as listed in Table 1-2. Specifications of the CFP4 hardware alarm pins are given in Ref.[1].

Table 1-2: Hardware Alarm Pins

Pin # | Symbol | Description | I/O | Logic | “H” | “L” | Pull-up /down |

12 | RX_LOS (PRG_ALRM) | Receiver Loss of Signal (Optionally configurable as Programmable Alarm after Reset1) | O | 3.3V LVCMOS | Loss of Signal2 | OK2 | |

15 | MOD_ABS | Module Absent | O | 3.3V LVCMOS | Absent | Present | Pull Down3 |

1 When Programmable Alarm is configured, MSA Default is HIPWR_ON.

2 Active High per CFP MSA MIS Ref. [3] when PRG_ALRM is configured for this pin.

3 Pull-Down resistor (<100Ohm) is located within the CFP4 module. Pull-up should be located on the host.

Hardware Alarm Pins: Functional Description

This alarm pin allows for the system to program module supported alarms to Hardware pin. The intention is to allow for maximum design and debug flexibility.

Programmable Alarm 1 Pin (PRG_ALRM1) is an output pin to the Host, operating with programmable logic. This pin can be re-programmed over MDIO registers to another MDIO alarm register while the module is in any steady state except Reset. CFP-MSA specifies the default function to be Receiver Loss of Signal (RX_LOS) indicator with active-high logic.

Not supported in CFP4 module

Not supported in CFP4 module

The Receiver Loss of Signal Pin (RX_LOS) is an output pin to the Host, operating with active-high logic. When asserted, it indicates received optical power in the CFP4 module is lower than the expected value. The optical power at which RX_LOS is asserted may be specified by other governing documents and the CFP4 module vendor as the alarm threshold level is application specific. The RX_LOS is the logic OR of the LOS signals from all the input receiving channels in a CFP4 module.

This pin can be optionally configured as Programmable Alarm 1 Pin after Reset. One MDIO register which defines if the module supports this optional configuration or not is prepared in NVRregion.

Please refer to Ref.[3] for more details.

Management Interface Pins

The CFP4 Module supports alarm, control and monitor functions via an MDIO bus. Upon module initialization, these functions are available. CFP4 MDIO electrical interface consists of 6pins including 2pins for MDC and MDIO, 3 Physical Port Address pins and th Global Alarm pin. MDC is the MDIO Clock line driven by the host and MDIO is the bidirectional data line driven by both the host and module depending upon the data directions. The CFP4 MDIO pins are listed in Table 1-3. Specifications of the CFP4 hardware management interface pins are given in Ref.[2] with the following changes listed below.

Table 1-3: Management Interface Pins (MDIO)

Pin # | Symbol | Description | I/O | Logic | “H” | “L” | Pull-up /down |

13 | GLB_ALRMn | Global Alarm | O | 3.3V LVCMOS | OK | Alarm | |

17 | MDC | MDIO Clock | I | 1.2V LVCMOS | |||

18 | MDIO | Management Data Input Output Bi-Directional Data | I/O | 1.2V LVCMOS | |||

19 | PRTADR0 | MDIO Physical Port address bit 0 | I | 1.2V LVCMOS | per CFP MSA MIS Ref. [3] | ||

20 | PRTADR1 | MDIO Physical Port address bit 1 | I | 1.2V LVCMOS | |||

21 | PRTADR2 | MDIO Physical Port address bit 2 | I | 1.2V LVCMOS | |||

CFP4 Management Interface Hardware Description

Per specifications given in Ref.[2] .

Hardware Signaling Pin Electrical Specifications

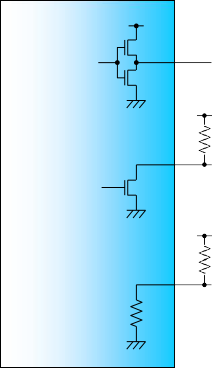

The hardware control and alarm pins specified as 3.3V LVCMOS functionally described above shall meet the characteristics described in Ref.[1]. Reference figures are provided regarding pin termination; see Figure 2-1 and 2-2.

Figure 2-1: Reference +3.3V LVCMOS Output Termination

Output

+3.3V

Open Drain Output

(GLB_ALRMn)

Output w/ PDR (MOD_ABS)

<100 ohm

CFP4 module

+3.3V

4.7k ~ 10k ohm

+3.3V

4.7k ~ 10k ohm

Figure 2-2: Reference 3.3V LVCMOS Input Termination

CFP4 modu Input w/PUR

4.7k~1 | e +3.3V 0k ohm | ||

Input w/PDR (MOD_RSTn) | |||

4.7k~1 |

0k ohm

| ||

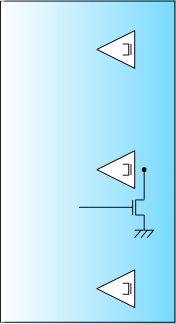

The MDIO interface pins specified as 1.2V LVCMOS functionally described above shall meet the characteristics described in Ref.[1]. Reference figure is provided regarding pin termination; see Fig.2-3.

Figure 2-3: Reference MDIO Interface Termination 2

CFP4 module

MDC

MDIO

PRTADR [n]

![]()

+1.2V

>= 250 ohm

![]()

![]()

![]()

![]()

<= 200 pF

![]()

![]()

+1.2V

>=250 ohm

![]()

![]()

![]()

![]()

<= 200 pF

![]()

Hardware Signaling Pin Timing Requirements

Per specifications given in Ref.[2]

![]()

![]()

![]()

2 The MSA recommends host termination resistor value of 560 Ohms, which provides the best balance of performance for both open-drain and active tri-state driver in the module. Host termination resistor values below 560Ohms are allowed, to a minimum of 250 Ohms, but this degrades active driver performance. Host termination resistor values above 560 Ohms are allowed but this degrades open-drain driver performance.

![]()

![]()

The above drawings, with maximum host load capacitance of 200pF, also define the measurement set-up for module MDC timing verification. The capacitor in the drawing indicates the stray capacitance on the line. Don’t put any physical capacitor on the line.

The CFP4 module utilizes MDIO IEEE Std 802.3TM-2012 clause 45 [8] for its management interface. The CFP4 MDIO implementation is defined in a separate document entitled, “CFP MSA Management Interface Specification” [3]. When multiple CFP4 modules are connected via a single bus, a particular CFP4 module can be selected by using the Physical Port Address pins.

![]()

![]()

Per specifications given in Ref. [1]

POWER SUPPLIES AND POWER DISSIPATION

The CFP4 module power supply and maximum power dissipation specifications are defined in Table 4-1.

The inrush current on the 3.3V power supply shall be limited by the CFP4 module to assure a maximum rate of change defined in Table 4-1.

The CFP4 module shall limit the turn-off current to assure a maximum rate of change per Table 4-1.

A host system will supply stable power to the module and guarantee that noise & ripple on the power supply does not exceed that defined in Table 4-1. A possible example of a power supply filtering circuit that might be used on the host system is a PI C-L-C filter. A module will meet all electrical requirements and remain fully operational in the presence of noise on the 3.3V power supply which is less than that defined in the table 4-1. The component values of power supply noise filtering circuit, such as the capacitor and inductor, must be selected such that maximum Inrush and Turn-off current does not cause voltage transients which exceed the absolute maximum power supply voltage, all specified in Table 4-1.

Table 4-1: Voltage Power Supply

Parameters | Symbol | Min | Typ. | Max | Unit | |

Absolute Maximum Power Supply Voltage | VCC | - | - | 3.6 | V | |

Total Power Dissipation | Class 1 | Pw | - | - | 1.5 | W |

Class 2 | - | - | 3 | |||

Class 3 | - | - | 4.5 | |||

Class 4 | - | - | 6 | |||

Class 5 | - | - | 7.5 | |||

Class 6 | - | - | 9 | |||

Low Power Mode Dissipation | Plow | - | - | 1 | W | |

Operating Power Supply Voltage | VCC | 3.2 | 3.3 | 3.4 | V | |

Operating Power Supply Current1 | Class 1 and 2 | ICC | - | - | 0.93 | A |

Class 3 and 4 | - | - | 1.87 | |||

Class 5 and 6 | - | - | 2.81 | |||

Inrush Current2 | Class 1, 2, 3 and 4 | I-inrush | - | - | 100 | mA/usec |

Turn-off Current | I-turnoff | -100 | - | - | ||

Inrush Current2 | Class 5 and 6 | I-inrush | - | - | 200 | |

Turn-off Current | I-turnoff | -200 | - | - | ||

Power Supply Noise | Vrip | - | - | 2% 3% | DC – 1MHz 1 – 10MHz | |

1 Maximum current per pin shall not exceed 500mA. Those power classes for which the maximum current per pin exceeds 500mA will require agreement from an electrical connector supplier.

2 For modules which present a small capacitive load to the host during hot plug (C <= 500nF), the portion of the inrush current due to charging the capacitor can be excluded from the total inrush current which must meet the maximum limit specification.

Per specifications given in Ref. [1].

OPTICAL CHARACTERISTICS

The CFP4 module will comply with standardized optical specifications such as the optical reaches specified in IEEE for datacom applications or in ITU-T for telecom applications. Some of the relevant reference documents are: IEEE Std. 802.3TM-2012, Telcordia GR-253, ITU-T G.691, ITU-T G.692, ITU-T G.693, and ITU-T G.959, ITU-T G.709.

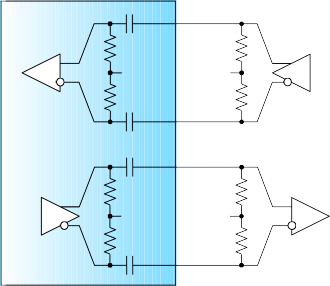

HIGH SPEED ELECTRICAL CHARACTERISTICS

The CFP4 Module high speed electrical interface supports the following configurations:

4 tx lanes + 4 rx lanes, each at 25 Gbit/s;

4 tx lanes + 4 rx lanes, each at 10 Gbit/s;

The high speed electrical interface shall be AC-coupled within the CFP4 module as is shown in Figure 4-1.

Figure 4-1: High Speed I/O for Data and Clocks

Input

50 ohm VTTin

50 ohm

50 ohm

VTTout 50 ohm

Output

50 ohm

VTTout 50 ohm

50 ohm

VTTin 50 ohm

CFP4 module

Per specifications given in Ref. [2].

Per specifications given in Ref. [2].

The 10 Gbit/s Transmitter Data is defined in IEEE Std. 802.3TM-2012 Annex 83A for XLPPI and Annex 83B for XLAUI, or XFI in SFF INF-8077i and SFI in SFF SFF-8431. Figure 4-1 shows the recommended termination for these circuits. Alternate signaling logic are OTL3.4 which are specified in ITU-T Recommendation G.709. Lane orientation and designation is specified in the pin-map tables given in Section 5.

The 10 Gbit/s Transmitter Data is defined in IEEE Std. 802.3TM-2012 Annex 83A for XLPPI and Annex 83B for XLAUI, or XFI in SFF INF-8077i and SFI in SFF SFF-8431. Figure 4-1 shows the recommended termination for these circuits. Alternate signaling logic are OTL3.4 which are specified in ITU-T Recommendation G.709. Lane orientation and designation is specified in the pin-map tables given in Section 5.

The CFP4 module may optionally support loopback functionality. Loopback commands are accessed via the MDIO management interface. Recommended loopback orientation implementation is TX0 to RX0. The host loopback and the network loopback are oriented per Figure 4-2 shown below. The capability to support the loopback functionality is dependent upon the interface IC technology, labeled as “Interface IC(s)” block in the figure. The CFP MSA module vendor will specify which loopback functionality, if any, is supported. For details on controlling the loopback mode, please refer to Ref. [3].

Figure 4-2: CFP4 Module Optional Loopback Orientation

DIO |

CFP4Module Controller | |

l/Alarm |

•, I ', I ..,..,.. | |

M

Contro

I

RX Optics

1 Optical 1

DMUX

I

Host MAC REFCLK

10p11-1

MCLK

coi,,1-1

TXDATA 4 lanes

Interface

IC(s)

Optical

TX Optics : MUX I

I ,,..,,,,..

,I --

J

Host loopback 4 Host lanes

Network loopback 4 or 10 Network lanes

![]()

For 4 x 25 Gbit/s host electrical interface applications, the host may supply a reference clock (REFCLK) at 1/160 electrical lane rate. The CFP4 module may use the 1/160 reference clock for transmitter path retiming, for example for Datacom applications.

The host may optionally supply a reference clock (REFCLK) at 1/40 electrical lane rate for 4 x 25 Gbit/s applications. The CFP4 module may optionally use the 1/40 reference clock for transmitter path retiming, for example for Telecom applications.

For 4 x 10 Gbit/s host electrical interface applications, the host may supply a reference clock (REFCLK) at 1/64 electrical lane rate. The CFP4 module may use the 1/64 reference clock for transmitter path retiming, for example for Datacom applications.

The host may optionally supply a reference clock (REFCLK) at 1/16 electrical lane rate for 4 x 10 Gbit/s applications. The CFP4 module may optionally use the 1/16 reference clock for transmitter path retiming, for example for Telecom applications.

When provided, the REFCLK shall be CML differential AC-coupled and terminated within the CFP4 module as shown in Figure 4-1. There is no required phase relationship between the data lanes and the reference clock, but the clock frequency shall not deviate more than specified in Table 4-2. For detailed clock characteristics please refer to the below table.

Table 4-2: Optional Reference Clock Characteristics

Min. | Typ. | Max. | Unit | Notes | ||

Impedance | Zd | 80 | 100 | 120 | Ω | |

Frequency | ||||||

Frequency Stability | f | -100 | 100 | ppm | For Ethernet applications; | |

-20 | 20 | For Telecom applications | ||||

Input Differential Voltage | VDIFF | 400 | 1200 | mV | Peak to Peak Differential | |

RMS Jitter1,2 | | 10 | ps | Random Jitter. Over frequency band of 10kHz < f < 10MHz | ||

Clock Duty Cycle | 40 | 60 | % | |||

Clock Rise/Fall Time 10/90% | tr/f | 200 | 1250 | ps | 1/160 of electrical lane rate for 4 x 25 Gbit/s and 1/64 of electrical lane rate for 4x 10 Gbit/s | |

50 | 315 | 1/40 of electrical lane rate for 4 x 25 Gbit/s and 1/16 of electrical lane rate for 4 x 10 Gbit/s | ||||

1 The spectrum of the jitter within this frequency band is undefined. The CFP4 shall meet performance requirements with worst case condition of a single jitter tone of 10ps RMS at any frequency between 10 KHz and 10 MHz.

2 For Telecom applications better jitter may be required.

An example of CFP4 clocking for 4 x 25 Gbit/s applications is shown in Figure 4-3. An example of CFP4 clocking for 4 x 10 Gbit/s applications is shown in Figure 4-4.

Not specified in this document.

Not specified in this document.

The CFP4 module may supply either a transmitter monitor clock or a receiver monitor clock for 4 x 25 Gbit/s applications. This option is not available for 4 x 10 Gbit/s applications. The monitor clock is intended to be used as a reference for measurements of the optical input or output. If provided, the clock shall operate at a rate relative to the optical network lane rate of 1/8 or 1/32 of 25 Gbit/s. Another option is a clock at 1/40 or 1/160 the rate of (host) transmitter electrical input data for 4 x 25 Gbit/s. Clock termination is shown in Figure 4-1. Detailed clock characteristics are specified in Table 4-3.

The user can select the source of the Monitor clock. MDIO register bits to select the source of the MCLK for CFP4 module is prepared in VR region. Please refer to Ref.[3] for details.

Table 4-3: Optional Monitor Clock Characteristics

Min. | Typ. | Max. | Unit | Notes | ||

Impedance | Zd | 80 | 100 | 120 | Ω | |

Frequency | ||||||

Output Differential Voltage | VDIFF | 400 | 1200 | mV | Peak to Peak Differential | |

Clock Duty Cycle | 40 | 60 | % | |||

Table 4-4: CFP4 Module Clocking Signals

Clock Name | Status | I/O | M x 25 Gbit/s Default Host Lane Rate | Optional Rate | |

Datacom 100GBASE-SR4/LR4/ER4 /SR10 | Telecom OTU4 | ||||

REFCLK | Optional | I | 1/160 (161.1328 MHz) or 1/40 (644.5313 MHz) | 1/160 (174.7031 MHz) or 1/40 (698.8123 MHz) | |

MCLK | Optional | O | 1/8 (3.22266 GHz) or 1/32 (805.665 MHz) or 1/40 (644.5313 MHz) or 1/160 (161.1328 MHz) | 1/8 (3.49406 GHz) or 1/32 (873.515 MHz) or 1/40 (698.8123 MHz) or 1/160 (174.7031 MHz) | |

Clock Name | Status | I/O | M x 10 Gbit/s Default Host Lane Rate | Optional Rate | |

Datacom 40GBASE-SR4/LR4/ER4 40GBASE-FR | Telecom OC-768/STM-256,OTU3 | ||||

REFCLK | Optional | I | 1/64 of host lane rate | 1/64 of host lane rate | 1/16 of host lane rate |

MCLK | Not Available | ||||

Note: Multi-protocol modules are recommended to adopt the clock rate used in Telecom applications.

Figure 4-3: Example of Clocking for 4 x 25 Gbit/s CFP4 Applications

Figure 4-4: Example of Clocking for 4 x 10 Gbit/s CFP4 Applications

![]()

![]()

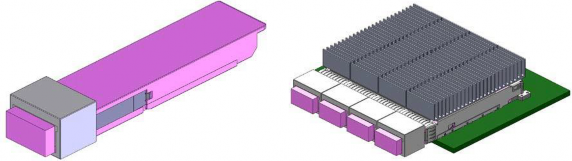

Mechanical Overview

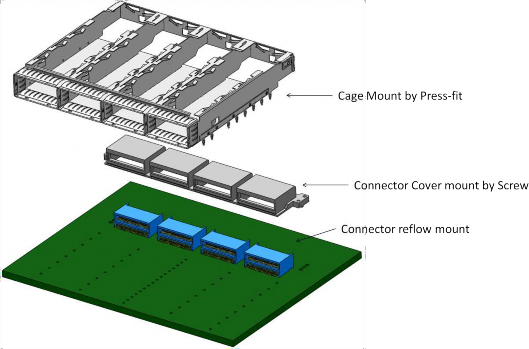

The CFP4 module is designed to be plugged into a host cage assembly with a riding heat sink. The cage assembly is fabricated within the host system and the CFP4 module may be inserted at a later time. Shown in Figure 5-1 is a drawing of the CFP4 module and CFP4 modules inserted into a host quad-port cage system with a riding heat sink.

Figure 5-1: CFP4 Module & CFP4 Module Mated in Host Quad Port System

Figure 5-2: Host Cage System and Mounting Method Overview

* Other mounting options are possible.

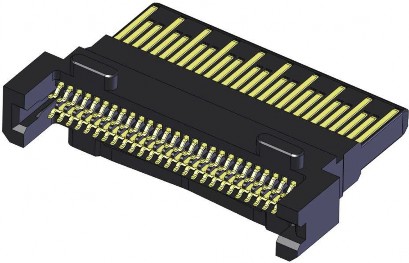

The CFP4 MSA specifies a two piece electrical connector for superior electrical performance and superior mechanical integrity. Shown in Figure 5-3 is the module plug connector assembly which is contained as a sub- component within the CFP4 module.

Figure 5-3: CFP4 Module Plug Connector Assembly

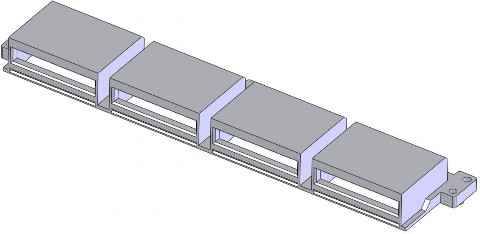

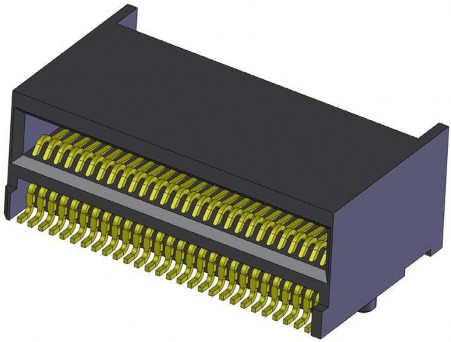

The CFP4 MSA specifies a two piece electrical connector for superior electrical performance and superior mechanical integrity. Shown in Figure 5-4 and Figure 5-5 are overview drawings of the host connector cover and the host connector assembly. These assemblies shall be built into the host system. The Host Connector shall be covered by the Host Connector Cover Assembly.

Figure 5-4: CFP4 Quad Port Host Connector Cover Assembly

Figure 5-5: CFP4 Host Connector Assembly

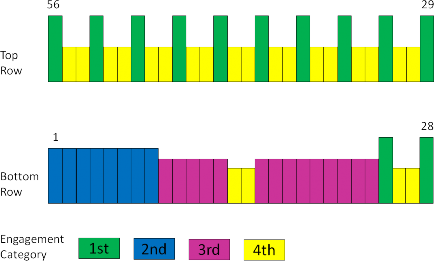

The module plug connector has a physical offset of metal contact pins to insure that certain signals make engagement between the module and host prior to other signals. There are four categories of pin engagement. A map of the connector engagement is shown in Figure 5-6. The connector pin map engagement order is guaranteed by the physical offset built into the module plug connector. The host connector has all contacts on the same plane without offset.

Figure 5-6: CFP4 Pin Map Connector Engagement

An overview of the CFP4 module dimensions is show in the below Figure 5-7. The CFP4 maximum header height is specified as shown in Figure 5-7. The detailed CFP4 module dimensions are located in a separate document hosted on the CFP MSA Website (www.cfp-msa.org). All mechanical hardware dimensions in this document are for reference only. Normative dimensions are found in the latest published CFP4 baseline drawing.

Figure 5-7: CFP4 Module Dimension Overview

The mechanical surface of flat top CFP4 module which may be in contact with the host riding heat sink assembly shall be compliant with specifications in Table 5-1. The parameters listed in Table 5-1 define the CFP4 module thermal interface and may be used by host system designers to specify the host cage assembly opening and riding heat sink for optimizing host system thermal management performance. Surface flatness and roughness parameters are specified per CFP4 module power class (see Table 4-1) to allow for optimization of module thermal performance and cost. Non-compliance to these specifications may cause significant thermal performance degradation. Only the top surface of the module is assumed to be used for heat transfer.

Table 5-1: CFP4 Mechanical Characteristics

Parameters | Power Class | Min. | Max. | Unit | Notes |

Weight | 1 – 6 | 90 | g | ||

Flatness | 1 | 0.15 | mm | ||

2 | 0.15 | mm | |||

3 | 0.12 | mm | |||

4 | 0.12 | mm | |||

Roughness | 1 | 3.2 | Ra | ||

2 | 3.2 | Ra | |||

3 | 1.6 | Ra | |||

4 | 1.6 | Ra | |||

Temperature Delta | 1 - 4 | 7 | °C | No heat sink; 200 lfm sideways airflow | |

Normal force exerted on module | 1 - 4 | 5 | 15 | N | Heat sink on module top surface |

As described in Section 1, the CFP4 module shall be hot pluggable. A consequence of the CFP4 module being hot pluggable is that an end user be equipped to insert and extract the module in the field. The required forces are specified below in Table 5-2.

Table 5-2: CFP4 Module Insertion, Extraction Forces

Max. | Unit | Notes | |

Maximum Insertion Force | 60 | N | Without Heat Sink |

Maximum Extraction Force | 50 | N | Without Heat Sink |

Minimum Module Retention Force | 90 | N | No damage to module below 90 N |

Minimum Cage Retention Force | 180 | N | No damage to cage latch below 180 N |

Minimum rating for host/module connector insertion/extraction is 200 cycles.

* Typical increase in those forces by adding heat sink is below 5N.

Host System Dimensions

The detailed CFP4 host system dimensions including host board layout are located in a separate document hosted on the CFP MSA Website (www.cfp-msa.org).

Riding Heat Sink

The riding heat sink and host cage top surface designs given in the latest published CFP4 baseline drawing are

only exemplary and are not required for compliance with the CFP4 MSA. Cage opening and heat sink specifications vary with host system design and thermal performance requirements. The heat sink/cage designs are therefore host system dependent and may be optimized by the system designer.

The riding heat sink illustrated in Figure 5-8 is for example only. The recommended material for the heat sink is aluminum.

The mounting dimensions for the Riding Heat Sink are shown below in Figure 5-9. The actual dimensions of the heat sink and cage top opening may be optimized for the particular host system.

Figure 5-9: Host Cage Top Surface Opening

The CFP4 module shall support LC, MTP12 and MTP24 optical connector types, as listed in Table 5-3.

Table 5-3: Optical Connectors 3

Pin # | Category | Reference Number |

LC Connector | TBA | TBA |

MPO12 Connector | TBA | TBA |

MPO24 Connector | TBA | TBA |

Not supported in the CFP4 module.

![]()

3 Other optical connectors may be supported

CFP4 host electrical connector supplier information will be added to Table 5-4 in a future release of this MSA.

Table 5-4: CFP4 Host Connector Assembly

Part Number | Supplier | Part Name |

TBA | TBA | Cage |

TBA | TBA | Host Connector Cover Assembly |

TBA | TBA | Host Connector |

The CFP4 connector has 56 pins which are arranged in Top and Bottom rows. The CFP4 connector supports the following configurations:

Four (4) 25Gbit/s TX lanes plus four (4) 25Gbit/s RX lanes;

The CFP4 pin-orderings are shown in Table 5-5. The CFP4 TOP pin-out definition uses the same pin-ordering convention as CFP and CFP2. There is also an optional CFP4 TOP ALT1 pin-out definition which follows the QSFP pin-ordering convention. All modules must support the baseline TOP pin-out definition. The optional TOP ALT1 pin-definition can be switched to after power-up by using MDIO commands to switch the pin-ordering.

For details, please refer to “CFP MSA Management Interface Specification”

Detailed description of the bottom row pins 1 through pin 28 are given in Table 5-6. Note the REFCLK pins are located on the top row along with the high-speed TX and RX data pins. A single-ended REFCLK is an

option. The CFP4 connector pin map orientation is shown in Figure 5-10.

Figure 5-10: CFP4 Connector Pin Map Orientation

\ I

\ I | |||

I I | |||

� I/ | |||

\ | I | ||

\ | |||

I | |||

I \ | |||

Pin view from top ==> Host

CFP4 | |

Bottom | |

1 | 3.3V_GND |

2 | 3.3V_GND |

3 | 3.3V |

4 | 3.3V |

5 | 3.3V |

6 | 3.3V |

7 | 3.3V_GND |

8 | 3.3V_GND |

9 | VND_IO_A |

10 | VND_IO_B |

11 | TX_DIS (PRG_CNTL1) |

12 | RX_LOS (PRG_ALRM1) |

13 | GLB_ALRMn |

14 | MOD_LOPWR |

15 | MOD_ABS |

16 | MOD_RSTn |

17 | MDC |

18 | MDIO |

19 | PRTADR0 |

20 | PRTADR1 |

21 | PRTADR2 |

22 | VND_IO_C |

23 | VND_IO_D |

24 | VND_IO_E |

25 | GND |

26 | (MCLKn) |

27 | (MCLKp) |

28 | GND |

Table 5-5: CFP4 4x25Gbit/s Pin Map

CFP4 | |

Top | |

56 | GND |

55 | TX3n |

54 | TX3p |

53 | GND |

52 | TX2n |

51 | TX2p |

50 | GND |

49 | TX1n |

48 | TX1p |

47 | GND |

46 | TX0n |

45 | TX0p |

44 | GND |

43 | (REFCLKn) |

42 | (REFCLKp) |

41 | GND |

40 | RX3n |

39 | RX3p |

38 | GND |

37 | RX2n |

36 | RX2p |

35 | GND |

34 | RX1n |

33 | RX1p |

32 | GND |

31 | RX0n |

30 | RX0p |

29 | GND |

CFP4 |

Top ALT1 |

GND |

TX0n |

TX0p |

GND |

TX1n |

TX1p |

GND |

TX2n |

TX2p |

GND |

TX3n |

TX3p |

GND |

(REFCLKn) |

(REFCLKp) |

GND |

RX3p |

RX3n |

GND |

RX2p |

RX2n |

GND |

RX1p |

RX1n |

GND |

RX0p |

RX0n |

GND |

`

REFCLK

(Optional)

MCLK = TX_MCLK + RX_MCLK

(Optional)

TX_DIS (PRG_CNTL1)

(Optionally configurable as Progammable Control after Reset)

RX_LOS (PRG_ALRM1)

(Optionally configurable as Progammable Alarm after Reset)

Table 5-6: CFP4 Bottom Row Pin Description for 4 x 25 Gbit/s Applications

PIN # | NAME | I/O | Logic | Description |

1 | 3.3V_GND | 3.3V Module Supply Voltage Return Ground, can be separate or tied together with Signal Ground | ||

2 | 3.3V_GND | 3.3V Module Supply Voltage Return Ground, can be separate or tied together with Signal Ground | ||

3 | 3.3V | 3.3V Module Supply Voltage | ||

4 | 3.3V | 3.3V Module Supply Voltage | ||

5 | 3.3V | 3.3V Module Supply Voltage | ||

6 | 3.3V | 3.3V Module Supply Voltage | ||

7 | 3.3V_GND | 3.3V Module Supply Voltage Return Ground, can be separate or tied together with Signal Ground | ||

8 | 3.3V_GND | 3.3V Module Supply Voltage Return Ground, can be separate or tied together with Signal Ground | ||

9 | VND_IO_A | I/O | LVCMOS w/ PUR | Module Vendor I/O A. Do Not Connect |

10 | VND_IO_B | I/O | Module Vendor I/O B. Do Not Connect | |

11 | TX_DIS (PRG_CNTL1) | I | Transmitter Disable for all lanes, "1" or NC = transmitter disabled, "0" = transmitter enabled (Optionally configurable as Programmable Control1 after Reset) | |

12 | RX_LOS (PRG_ALRM1) | O | LVCMOS | Receiver Loss of Optical Signal, "1": low optical signal, "0": normal condition (Optionally configurable as Programmable Alarm1 after Reset) |

13 | GLB_ALRMn | O | LVCMOS | Global Alarm. “0": alarm condition in any MDIO Alarm register, "1": no alarm condition, Open Drain, Pull Up Resistor on Host |

14 | MOD_LOPWR | I | LVCMOS w/ PUR | Module Low Power Mode. "1" or NC: module in low power (safe) mode, "0": power-on enabled |

15 | MOD_ABS | O | GND | Module Absent. "1" or NC: module absent, "0": module present, Pull Up Resistor on Host |

16 | MOD_RSTn | I | LVCMOS w/ PDR | Module Reset. "0" resets the module, "1" or NC = module enabled, Pull Down Resistor in Module |

17 | MDC | I | 1.2V CMOS | Management Data Clock (electrical specs as per IEEE Std 802.3-2012) |

18 | MDIO | I/O | 1.2V CMOS | Management Data I/O bi-directional data (electrical specs as per IEEE Std 802.3ae- 2008 and ba-2010) |

19 | PRTADR0 | I | 1.2V CMOS | MDIO Physical Port address bit 0 |

20 | PRTADR1 | I | 1.2V CMOS | MDIO Physical Port address bit 1 |

21 | PRTADR2 | I | 1.2V CMOS | MDIO Physical Port address bit 2 |

22 | VND_IO_C | I/O | Module Vendor I/O C. Do Not Connect | |

23 | VND_IO_D | I/O | Module Vendor I/O D. Do Not Connect | |

24 | VND_IO_E | I/O | CML | Module Vendor I/O E. Do Not Connect |

25 | GND | |||

26 | (MCLKn) | O | For optical waveform testing. Not for normal use. | |

27 | (MCLKp) | O | CML | For optical waveform testing. Not for normal use. |

28 | GND |

CFP4 Bail Latch Color Coding and Labeling

Table 5-7: CFP4 Bail Latch Color Coding

Bail Latch Color Minimum reach & Minimum loss | Bail Latch Band | |||

10G/fiber One center black band (010) | 25G/fiber (or 20G/fiber) Two side black bands (101) | 50G/fiber (or 40G/fiber) Three black bands (111) | 100G/fiber No bands (solid color) (000) | |

Beige 100m & 2dB (MMF) | 100GE-SR10 Mx 40GE-SR4 Nx 10GE-SR | 100GE-SR4 | Mx “40GE-SR”* | “100GE-SR”* |

Yellow 500m & 2.5dB (SMF) | “40GE-nR4”* parallel | “100GE-nR4”* parallel | “100GE-nR2”* parallel | “100GE-nR4”* |

Green 2km & 4dB (SMF) | “100GE-FR4”* parallel | Mx 40GE-FR | “100GE-FR4”* | |

Lighter Blue 10km & 6dB | Nx 10GE-LR | Mx 40GE-LR4 | 100GE-LR4 | |

Lighter Red 30km/40km | Nx 10GE-ER | 100G DD DWDM | Mx 40GE-ER4 | 100GE-ER4 |

White ≤ 80km | Nx “10GE-ZR”* | 100G DD DWDM | Mx “40GE-ZR4”* | “100GE-ZR4”* 100G Coh. DWDM |

Note 1: Link budget = Minimum penalty [function of minimum reach] + minimum loss Note 2: * For potential future application; Not currently a standard nor MSA.

Note 3: Bail latch without any color (including no black bands; metal only) indicates a module that does not fit into any of the defined categories.

The CFP4 module should be clearly labeled. The complete labeling need not be visible when the CFP4 module is installed in the host cage assembly. A recessed area on the bottom of the CFP4 module, as shown in Figure 5-11, is the recommended location for module label.

Figure 5-11: CFP4 Module Label Recess

![]()

![]()

Per specifications given in Ref. [1]. End of Document